Tel:+86-13877625497

Name:Mr.Chintu

Fax:

Website:https://www.cokgc.com/

E-mail:COMKGC@163.COM

| MECHANICAL SEAL |

|

Mechanical seal for pump |

Mechanical seal for pump |

|

Mechanical seal for pump |

Mechanical seal for pump |

|

Mechanical seal for pump |

Mechanical seal for pump |

|

Mechanical seal for pump |

Mechanical seal for pump |

|

Mechanical seal for pump |

Mechanical seal for pump,Model pump/type seal: LBJ-GJ99 |

|

Mechanical seal LCF50/460 - HTM 55S220Z |

|

|

Mechanical seal (for ball pump) Bugmann MG 1/35Z |

MG 1/35Z or equivalent |

|

Mechanical seal for pump model LBJ-GJ-99 |

LBJ-GJ-99 or equivalent |

|

Mechanical seal for pump HR325/170-G11-EX1 |

Mechanical seal for pump HR325/170-G11-EX1( □600X-TLR,□700X-TLR,□800X-TLR?whick type?) |

|

Mechanical seal for pump LBJ-QZ3125/0901003 |

LBJ-QZ3125/0901003 or equivalent |

|

Mechanical seal for pump M7N - 60 |

M7N - 60 or equivalent |

|

Mechanical seal IHE 100-65-315 ( including accessories ) |

IHE 100-65-315 ( kèm theo phụ kiện ) or equivalent |

|

Mechanical seal KWPK80-250 for pump |

KWPK80-250 or equivalent (pump or seal photo required) |

|

Mechanical seal M7N-55 |

M7N-55 or equivalent |

|

Mechanical Seal ESD42L060R31V6 |

ESD42L060R31V6 or equivalent |

|

SEAL |

1. Vành nén tết chèn cổ trục máy nghiền xỉ phi 230 *146 |

|

SEAL |

2. Vòng chèn cổ trục bơm ngưng phi 120x130x25 gỗ nhíp |

|

SHORT TEXT |

LONG DESCRIPTION |

|

Mechanical Seal |

1. Mechanical Seal |

|

Mechanical Seal |

2. Mechanical Seal |

|

Mechanical Seal |

3. Mechanical Seal |

|

Mechanical Seal |

4. Mechanical Seal ekato |

|

Burgman seal MG 1/35Z |

|

Seal model: LBJ-QZ3125/0901003 |

|

Seal mdel; KWPK 80-250 |

|

Seal Model: KWPK65-200 |

|

seal HR325/170-G1-EX/525 |

|

Seal :ZGJ-45 |

|

Seal: ZGJ-60 |

|

Mechanical Seal Model LBJ-GJ-92-00 |

|

Mechanical Seal Model LBJ-GJ-96-00 |

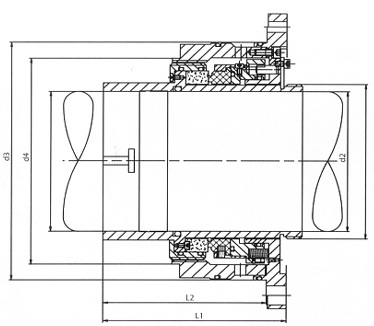

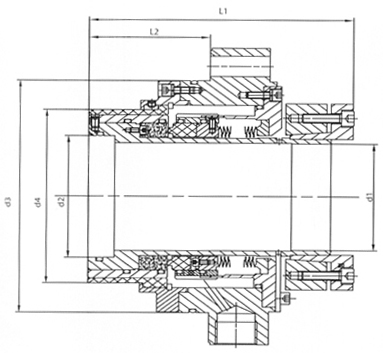

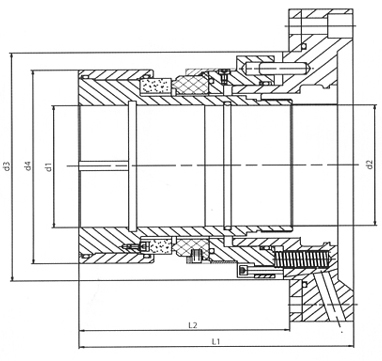

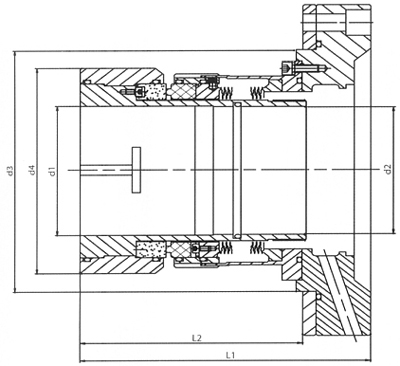

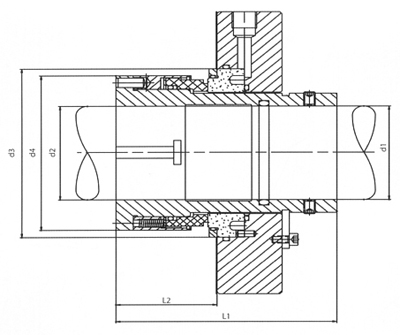

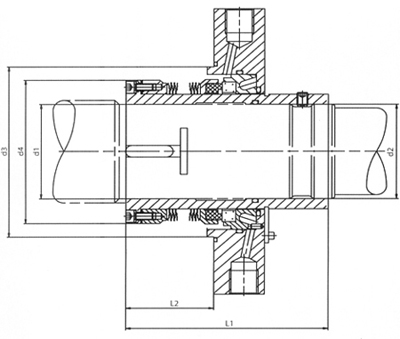

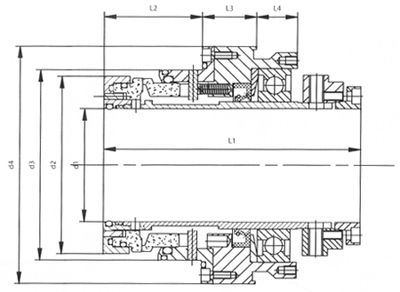

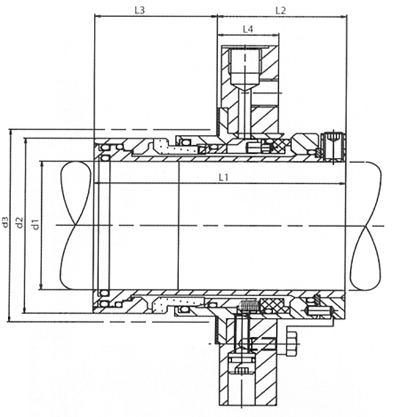

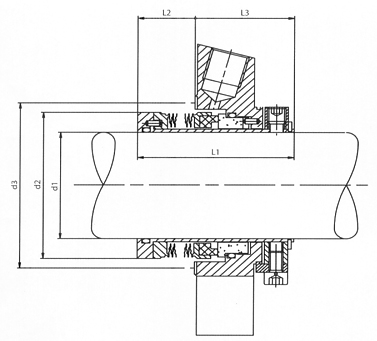

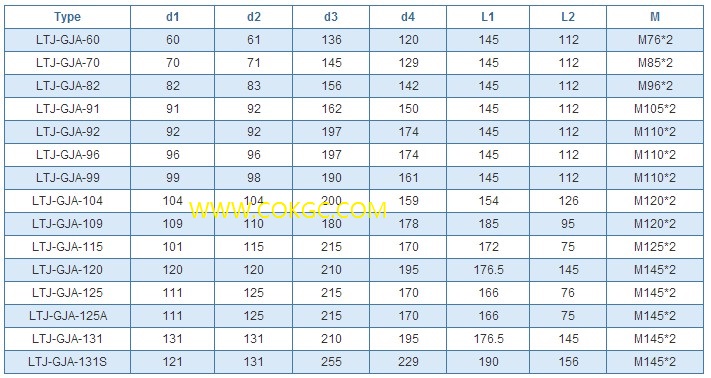

Bring about balanced

Bring more spring design

Bring equipped with cooling system

This series mechanical seal used in thermal power plant boiler feed pump V

p≤3.0MPa

t≤250℃

v≤50m/s

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

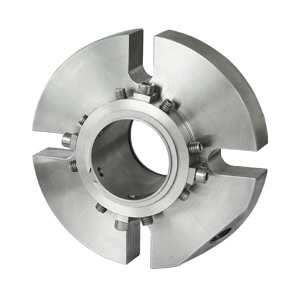

| ▲ Cartridge ▲ Balanced ▲ Multi-spring ▲ Equipped with cooling system Machnanical seals of the LTJ-GJA series are designed for boiler feed pump in thermal power plant. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| d=60~300mm p≤4.0MPa t≤250℃ v≤50m/s |

|

LBJ-GJA

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LTJ-GJB

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LBJ-GJB

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LTJ-QZ

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LBJ-QZ

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LTJ-NJA

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

LTJ-NJB

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LTJ/CS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LBJ/CS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

序号 |

转速2900(r/min) |

转速1450(r/min) |

||||||||

|

流量(m3/h) |

扬程 |

功率 |

轴功率(KW) |

汽蚀余量(NPSH)r |

流量(m3/h) |

扬程 |

功率 |

轴功率(KW) |

汽蚀余量(NPSH)r |

|

|

IHE32-25-125 |

3.6 |

16 |

41 |

0.39 |

||||||

|

IHE32-25-160 |

3.6 |

25 |

32 |

0.77 |

||||||

|

IHE32-25-200 |

3.6 |

41 |

23 |

1.75 |

||||||

|

IHE40-32-125 |

7.2 |

16 |

49 |

0.63 |

||||||

|

IHE40-32-160 |

7.2 |

26 |

44 |

1.14 |

||||||

|

IHE40-32-200 |

7.2 |

40 |

35 |

2.21 |

||||||

|

IHE40-32-250 |

7.2 |

65 |

26 |

4.91 |

||||||

|

IHE50-32-125 |

12.5 |

20 |

51 |

1.33 |

2.0 |

6.3 |

5 |

44 |

0.19 |

1.2 |

|

IHE50-32-160 |

12.5 |

32 |

46 |

2.37 |

2.0 |

6.3 |

8 |

39 |

0.35 |

1.2 |

|

IHE50-32-200 |

12.5 |

50 |

39 |

4.36 |

2.0 |

6.3 |

12.5 |

33 |

0.65 |

1.2 |

|

IHE50-32-250 |

12.5 |

80 |

33 |

8.25 |

2.0 |

6.3 |

20 |

27 |

1.27 |

1.2 |

|

IHE65-50-125 |

25 |

20 |

62 |

2.2 |

2.0 |

12.5 |

5 |

55 |

0.31 |

1.2 |

|

IHE65-50-160 |

25 |

32 |

57 |

3.82 |

2.0 |

12.5 |

8 |

51 |

0.53 |

1.2 |

|

IHE65-40-200 |

25 |

50 |

52 |

6.55 |

2.0 |

12.5 |

12.5 |

46 |

0.93 |

1.2 |

|

IHE65-40-250 |

25 |

80 |

46 |

11.84 |

2.0 |

12.5 |

20 |

39 |

1.75 |

1.2 |

|

IHE65-40-315 |

25 |

125 |

39 |

21.8 |

2.0 |

12.5 |

32 |

33 |

3.3 |

1.2 |

|

IHE80-65-125 |

50 |

20 |

69 |

3.95 |

2.4 |

25 |

5 |

64 |

0.53 |

2.0 |

|

IHE80-65-160 |

50 |

32 |

67 |

6.5 |

2.4 |

25 |

8 |

62 |

0.88 |

2.0 |

|

IHE80-50-200 |

50 |

50 |

63 |

10.8 |

2.4 |

25 |

12.5 |

57 |

1.49 |

2.0 |

|

IHE80-50-250 |

50 |

80 |

58 |

18.78 |

2.4 |

25 |

20 |

52 |

2.62 |

2.0 |

|

IHE80-50-315 |

50 |

125 |

52 |

32.73 |

2.4 |

25 |

32 |

43 |

5.07 |

2.0 |

|

IHE80-65-125 |

||||||||||

|

IHE100-80-125 |

100 |

20 |

73 |

7.46 |

4.5 |

50 |

5 |

69 |

0.99 |

3.6 |

|

IHE100-80-160 |

100 |

32 |

73 |

11.9 |

4.3 |

50 |

8 |

69 |

1.58 |

3.4 |

|

IHE100-65-200 |

100 |

50 |

72 |

18.9 |

3.9 |

50 |

12.5 |

68 |

2.5 |

2.5 |

|

IHE100-65-250 |

100 |

80 |

67 |

32.5 |

3.6 |

50 |

20 |

63 |

4.3 |

2.5 |

|

IHE100-65-315 |

100 |

125 |

62 |

54.9 |

3.2 |

50 |

32 |

58 |

7.51 |

2.0 |

|

IHE125-100-200 |

200 |

50 |

77 |

35.4 |

5.0 |

100 |

12.5 |

73 |

4.66 |

2.9 |

|

IHE125-100-250 |

200 |

80 |

75 |

58.1 |

4.5 |

100 |

20 |

71 |

7.67 |

2.3 |

|

IHE125-100-315 |

200 |

125 |

70 |

97.27 |

5.0 |

100 |

32 |

67 |

13.01 |

2.5 |

|

IHE125-100-400 |

100 |

50 |

62 |

21.96 |

2.8 |

|||||

|

IHE150-125-250 |

200 |

20 |

77 |

14.1 |

2.8 |

|||||

|

IHE150-125-315 |

200 |

32 |

75 |

23.2 |

2.8 |

|||||

|

IHE150-125-400 |

200 |

50 |

70 |

38.9 |

2.5 |

|||||

|

IHE200-150-250 |

400 |

20 |

79 |

27.58 |

4.5 |

|||||

|

IHE200-150-315 |

400 |

32 |

79 |

44.1 |

4.5 |

|||||

|

IHE200-150-400 |

400 |

50 |

78 |

69.8 |

4.5 |

|||||

|

OEM AND SUPPLIER DETAILS(KGC): |

|

NANNING KAIGANG CRANE CO. LTD No.31 Jinzhou Road, Nanning, Guangxi, China Website:WWW.COKGC.COM Contact:Mr.Chintu Wen Mobile:0086 13877625497 Email:comkgc@163.com Gmail:pglchintu@gmail.com Skype:pglchintu |

|

FACE MECH SEAL |

FACE, MECHANICAL SEAL; |

|

SEAT MECH SEAL;DMNSN 100MM |

SEAT, MECHANICAL SEAL; |

|

O RNG SET;TYP MECHANICAL SEAL |

O RING SET; |

|

SEAT MECH SEAL;DMNSN OCCW,MTRL CARBON |

SEAT, MECHANICAL SEAL; |

|

FACE MECH SEAL;TYP SEAL FACE;0 |

FACE, MECHANICAL SEAL; |

|

O RNG SET;TYP NA,MTRL EPDM |

O RING SET; |

|

SEAL MECH;TYP TYPE SHF1/125 |

SEAL, MECHANICAL; |

|

SEAL MECH;TYP SHF1/125 |

SEAL, MECHANICAL; |

|

1 |

Seal Face |

|

2 |

Seal Seat |

|

3 |

O-Ring Set |

|

4 |

Seal Seat |

|

5 |

Seal Face |

|

6 |

O-Ring Set |

|

7 |

Mechanical Seal Drive End |

|

8 |

Mechanical Seal Non-Drive End |

|

SHORT TEXT |

LONG DESCRIPTION |

|

FACE MECH SEAL |

FACE, MECHANICAL SEAL; |

|

SEAT MECH SEAL;DMNSN 100MM |

SEAT, MECHANICAL SEAL; |

|

O RNG SET;TYP MECHANICAL SEAL |

O RING SET; |

|

SEAT MECH SEAL;DMNSN OCCW,MTRL CARBON |

SEAT, MECHANICAL SEAL; |

|

FACE MECH SEAL;TYP SEAL FACE;0 |

FACE, MECHANICAL SEAL; |

|

O RNG SET;TYP NA,MTRL EPDM |

O RING SET; |

|

SEAL MECH;TYP TYPE SHF1/125 |

SEAL, MECHANICAL; |

|

SEAL MECH;TYP SHF1/125 |

SEAL, MECHANICAL; |

|

→We quotation |

→You side Released PO to us |

→We signed PO |

→You side payment |

→We delivery goods to your side. |