Tel:+86-13877625497

Name:Mr.Chintu

Fax:

Website:https://www.cokgc.com/

E-mail:COMKGC@163.COM

|

AKH MOTOR

|

AKH MOTOR, FRAME : SE100LG- 04/B, 3.7KW, 400V, 500RPM, FOOT MOUNTED WITH BRAKE , S1, IP55, MAKE : AKH. |

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Company Services Motors Applications Latest Info Contact Downloads

Motor overviewMotor serie 1Motor serie 2Motor serie 3Motor serie 4Motor serie 5Motor serie 6Motor serie 7Motor serie 8Motor serie 9Motor serie 10Motor serie 11Motor serie 12Energy efficiency

Innovative and highly efficient special motors

Since 1924, KATT Motoren develops and manufactures (from 2002 Antriebstechnik KATT Hessen) electric motors customized for the most varied applications.

Due to the many years of experience, a very broad range of products has developed.

Thus, today we are in the position to supply motors for the most varied applications and develop and manufacture motors for new applications with special requirements at very short notice.

Thereby, due to our innovative development team and the extraordinarily high range of manufacturing, no limits are set technically within the framework of our range of products.

Rating range

power from 1 to 1000 kW

Speed up to 20.000 rpm

Axle height 90 to 500 mm

We have subdivided a major part of our range of products into individual groups of product.

If a suitable motor for your application cannot be found in the range of products in the previously mentioned rating range, we request that you nevertheless contact us with your requirements.

Due to the wide range of products, it is not possible for us to practically classify all motors into groups of products.

Motors and generators

Three-phase asynchronous motors with squirrel-cage and slip ring rotor

Three-phase synchronous motors

Motor serie 01

Squirrel-cage motors with and without built-on components

Shaft height: 90 up to 500

Power: up to 1.000 kW

Speed range: up to 18.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Option: IC 416 (separate cooling)

Option: IC 70W (water-cooling)

Degree of protection: IP 54 (up to IP 56)

Motor serie 02

Slip ring motors with and without built-on components

m2_5_0.png, 58kB

Shaft height: 90 up to 450 mm

Power: up to 450 kW

Speed range: up to 3.600 rpm.

Rotorsp. 80 up to 600 V load-dependent

Mounting B3 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Option: IC 416 (separate cooling)

Degree of protection: IP 54 (up to IP 56)

Motor serie 03

Slewing and lifting equipment motors

m3_5_0.png, 56kB

Shaft height: 112 up to 450 mm

Power: up to 350 kW

Speed range: up to 6.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Option: IC 416 (separate cooling

Degree of protection: IP 54 (up to IP 56)

Motor serie 04

Flat-frame motors

m4_5_0.png, 43kB

Shaft height 90 up to 500 mm

Power: up to 132 kW

Speed range: up to 12.000 rpm.

Mounting: B3 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Option: IC 416 (separate cooling

Degree of protection: IP 54 (up to IP 56)

Motor serie 05

Pump -, fan-, agitator motors

m5_5_0.png, 58kB

Shaft height: 90 up to 500 mm

Power: up to 1.000 kW

Speed range: up to 18.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Option: IC 416 (separate cooling

Option: IC 70W (water-cooling)

Degree of protection: IP 54 (up to IP 56)

Motor serie 06

Static-torque motors

m6_5_0.png, 56kB

Shaft height: 80 up to 200 mm

Power: 1,4 up to 100 Nm

Speed range: 0 up to 3.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 410 (convection cooling)

Option: IC 416 (separate cooling)

Degree of protection: IP 54 (up to IP 56)

Motor serie 07

Circulating fan-drive motors

m7_5_0.png, 49kB

Shaft height: 80 up to 355 mm

Power: up to 160 kW

Speed range: 0 bis 3.000 U/min

Mounting: B5 (more by IEC 600347)

Cooling: IC 411 (self-ventilated)

Cooling: oder IC 70W (water-cooling

Option: IC 416 (separate cooling)

Degree of protection: IP 54 (up to IP 55)

Motor serie 08

Main drive motors, frameless design, air-cooled

m8_5_0.png, 52kB

Shaft height: 100 up to 400 mm

Power: up to 600 kW

Speed range: 0 up to 12.000 rpm.

Mounting: B35 (more by IEC 600347)

Cooling: IC 416 (separate cooling)

Degree of protection: Degree of protection: IP 54 (up to IP 55)

Motor serie 09

Main drive motors, ultra compact, water- cooled

m9_5_0.png, 43kB

Shaft height: 112 up to 180 mm

Power: up to 330 kW

0 up to 12.000 rpm. up to 18.000 rpm.

Mounting: B3, B5

(more by IEC 600347)

Cooling: IC 70 W (water-cooling)

Degree of protection: IP 54 (up to IP 56)

Motor serie 10

Main drive motors, air-cooled or with heat exchanger

m10_5_0.png, 55kB

Shaft height: 160 up to 500 mm

Power: up to 1.000 kW

Speed range: up to 18.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 06 (open-circuit cooling)

Option: IC 86W (LuftWasserWärmetauscher)

Degree of protection: IP 23 (IP 54 mit Wärmetauscher)

Motor serie 11

Main drive motors, water-cooled or with combined water-air-cooling

m11_5_0.png, 57kB

Shaft height: 100 up to 500 mm

Power: up to 1.000 kW

Speed range: 0 up to 18.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 70W (water-cooling)

Option: IC 70W and IC 06

Degree of protection: IP 54 (IP 23 combined Cooling)

Motor serie 12

Additional motor series: submersible motor, theatre motors, stainless steel motors

m12_5_0.png, 52kB

Shaft height: 90 up to 500 mm

Power: up to 500 kW

Speed range: up to 6.000 rpm.

Mounting: B3, B5 (more by IEC 600347)

Cooling: IC 410

Degree of protection: IP 68

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Company Services Motors Applications Latest Info Contact Downloads

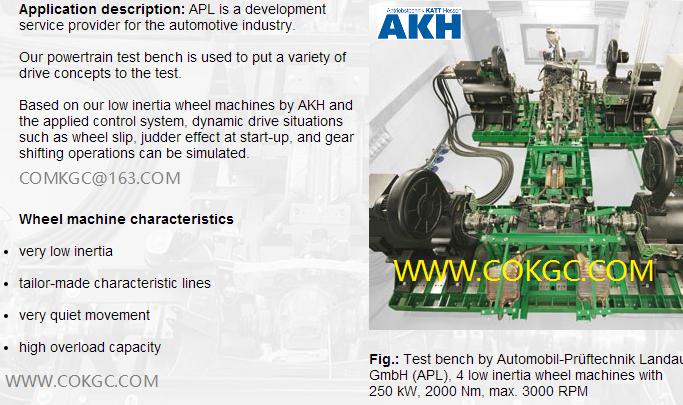

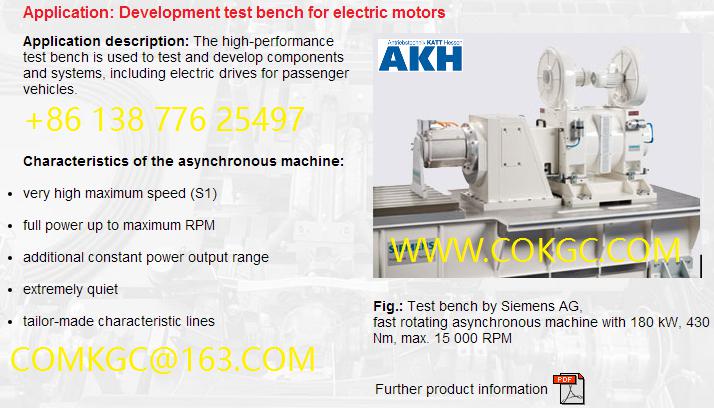

Machine / plant engineeringTest bench technologyE- mobilityWood/stone processingPumps/fans/agitatorsCrane construction/lifting technologyDrive technologySteel industry

Motors for machine and plant engineering

High pole, especially customized stators with special winding for presses and high dynamic motors with low inertia for cross-cutting systems are only two applications that can be reliably served using our special motors.

Application: Cut-to length line systems

The systems are used for cross-cutting metal strips of all types, particularly also for large material thicknesses. maschinenbau01.jpg, 21kB

Fig.: Cut-to length line system Co. Ungerer Systeme GmbH

Motor characteristics

low inertia due to very high dynamics

high overload capacity due to large cutting torque

particularly robust mechanical design due to very short acceleration and braking procedures and high peak torques whilst cutting

Further product information

pdf.gif, 1,1kB

Applications: Spindle presses and forging hammers

The directly driven spindle presses from LASCO (refer to Fig. right) enables high efficiency due to frequency converter operation, through energetic recovery of the brake energy and precise energy regulation (high process reliability and reproducibility).

lasco.jpg, 19kB

Characteristics of spindle drive:

high number of poles (e-g. 42-pole)

high torques and inertia masses (e.g. 55.000Nm acceleration torque)

design for FU operation with windings operating in parallel

Characteristics of hydraulic pump drive for forging hammer:

high resistance to vibration (up to 20 G)

thermal reserves for long service life

Further applications in machine and plant engineering

drives for machine tools

sluice drives

construction machines

plastic machines

paper machines

printing machines

textile machines

wood, glass, ceramic and stone processing machines

packaging machines

special machines

References: ADE-Werk GmbH, Eickhoff Maschinenfabrik GmbH, Bornemann Maschinebau GmbH, Dieffenbacher GmbH, Lasco Umformtechnik GmbH, Ungerer Systeme GmbH & Co. KG, WAFIOS Umformtechnik GmbH, Wohlenberg Werkzeugmaschinen GmbH

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

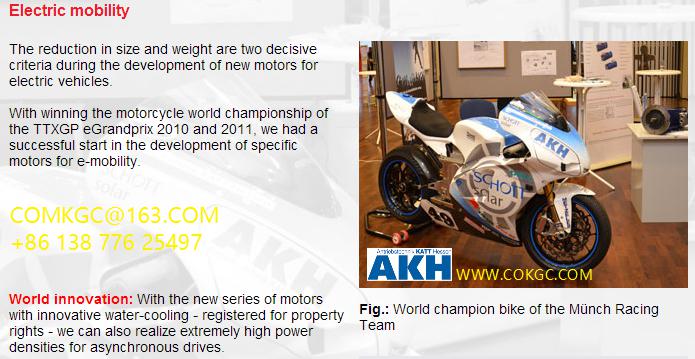

Electric mobility

elektromobilitaet.jpg, 29kB

The reduction in size and weight are two decisive criteria during the development of new motors for electric vehicles.

With winning the motorcycle world championship of the TTXGP eGrandprix 2010 and 2011, we had a successful start in the development of specific motors for e-mobility.

World innovation: With the new series of motors with innovative water-cooling - registered for property rights - we can also realize extremely high power densities for asynchronous drives.

Fig.: World champion bike of the Münch Racing Team

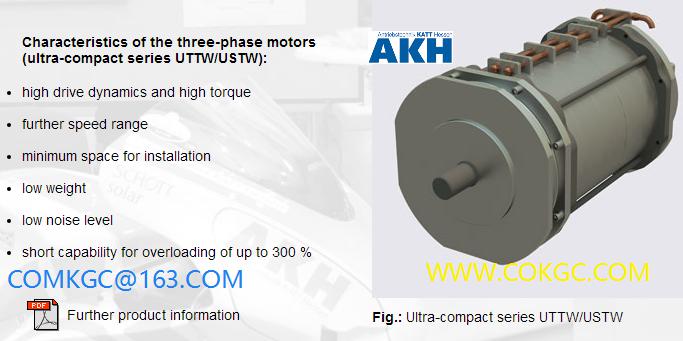

Characteristics of the three-phase motors (ultra-compact series UTTW/USTW):

high drive dynamics and high torque

further speed range

minimum space for installation

low weight

low noise level

short capability for overloading of up to 300 %

elektromobilitaet.jpg, 29kB

Fig.: Ultra-compact series UTTW/USTW

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Pumps / fans / agitators

industrieofen.jpg, 12kB

The requirements in this wide field of application are very different, e.g.

Fig.: Industrial furnace plant from LOI

special shaft geometries

very long shafts and / or large diameter

special shaft material

special bearing for high axial and radial forces

high maximum speeds

quadratic load characteristic curve

high energy efficiency due to continuous operation

NEW: Air-cooled special motors in IE3

The highly efficient external and self-ventilated special motors are used, et al. as pump motors in vertical multi-stage process pumps.

This application is characterized by a quadratic load characteristic curve, high mechanical and thermal requirements on the bearing, high drive speeds and rigorous conditions of use.

pdf.gif, 1,1kB

Further product information

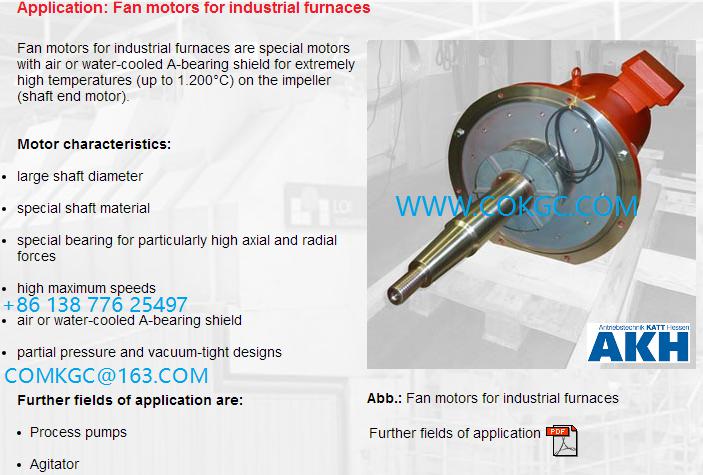

Fan motors for industrial furnaces are special motors with air or water-cooled A-bearing shield for extremely high temperatures (up to 1.200°C) on the impeller (shaft end motor).

Motor characteristics:

large shaft diameter

special shaft material

special bearing for particularly high axial and radial forces

high maximum speeds

air or water-cooled A-bearing shield

partial pressure and vacuum-tight designs

Further fields of application are:

Process pumps

Agitator

Centrifuges

Extruder

Application: Fan motors for industrial furnaces

lueftermotor.jpg, 15kB

Abb.: Fan motors for industrial furnaces

Further fields of application

pdf.gif, 1,1kB

References: Helmke Orbis, LOI Thermoprocess GmbH, Neudecker und Jolitz GmbH & Co. KG

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Crane construction / lifting technology

For many years we supply special motors for crane installations globally.

Depending on the application, these modern three-phase squirrel-cage motors with excellent operating characteristics and high dynamics for operation on frequency converters, pole-changing motors or three-phase slip-ring motors (partly with eddy current brake installed).

In the meantime, the latter are primarily demanded if replacement motors are required for existing installations.

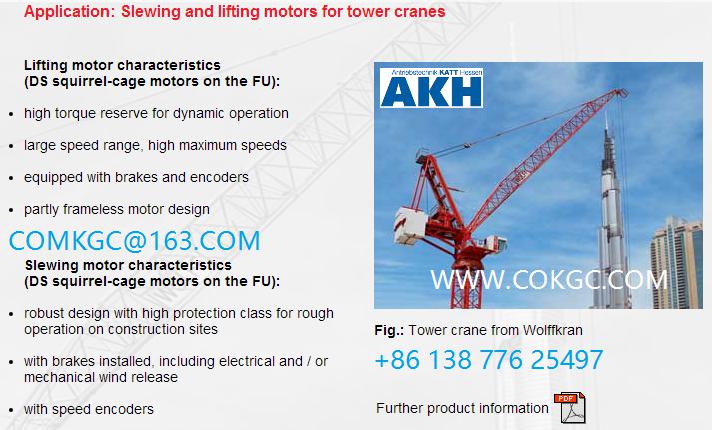

Application: Slewing and lifting motors for tower cranes

Lifting motor characteristics

(DS squirrel-cage motors on the FU):

high torque reserve for dynamic operation

large speed range, high maximum speeds

equipped with brakes and encoders

partly frameless motor design

kranbau.jpg, 9,5kB

Fig.: Tower crane from Wolffkran

Slewing motor characteristics

(DS squirrel-cage motors on the FU):

robust design with high protection class for rough operation on construction sites

with brakes installed, including electrical and / or mechanical wind release

with speed encoders

Further product information

pdf.gif, 1,1kB

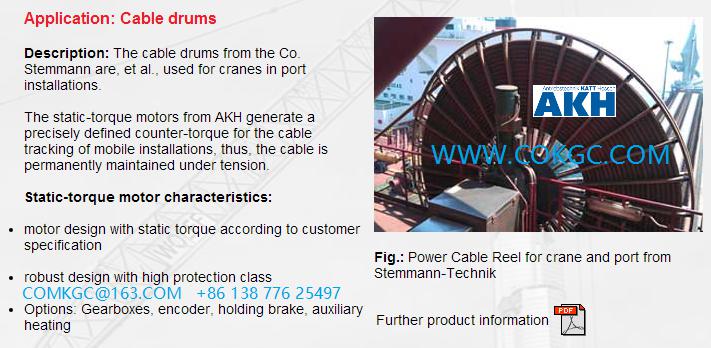

Application: Cable drums

Description: The cable drums from the Co. Stemmann are, et al., used for cranes in port installations.

The static-torque motors from AKH generate a precisely defined counter-torque for the cable tracking of mobile installations, thus, the cable is permanently maintained under tension.

Static-torque motor characteristics:

motor design with static torque according to customer specification

robust design with high protection class

Options: Gearboxes, encoder, holding brake, auxiliary heating

leitungstrommeln.jpg, 13kB

Fig.: Power Cable Reel for crane and port from Stemmann-Technik

Further product information

pdf.gif, 1,1kB

References: ABUS Kransysteme GmbH, BBH Systems GmbH, Dematic GmbH, Demag Cranes & Components GmbH, KÜHNEZUG Hebezeuge GmbH & Co.KG, Liebherr, Stalvoss GmbH & Co. KG, Stemmann-Technik GmbH, Wolffkran GmbH,

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Drive technology

antriebstechnik_klein01.jpg, 11kB

Fig.: SEW motor

We supply special motors to the renowned, large manufacturers of standard electric motors and gearboxes, as well as engineering consultants that have specialized in the project planning of drive technology using special motors.

Referenzen: SEW-EURODRIVE GmbH & Co KG, Siemens AG, J. Helmke & Co., Antriebssysteme GmbH Orgeldinger, E. Kretzschmar,

Kurt Maier Motor-Press GmbH, Lenze GmbH & Co. KG, Stöwer Antriebstechnik GmbH

Further product information

+++++++++++++WWW.COKGC.COM mailto:COMKGC@163.COM++++++++++++

Steel industry

stahlindustrie.jpg, 25kB

We supply three-phase slip-ring and three-phase squirrel-cage motors to the steel industry for different applications, et al. as replacement motors.

Depending on the task, the motors are designed, with regard to the motor characteristics and mechanical interface, so that these can replace the old motors 1:1. This includes supplying the motors in accordance with the different works standards of, e.g. Thyssen-Krupp, SAB, VIK etc.

Further applications:

roller conveyor drives

drives for lifting and crane installations

cable drums

Further applications:

|

→We quotation |

→You side Released PO to us |

→We signed PO |

→You side payment |

→We delivery goods to your side. |