Picture

Contact

Address:No.31 Jinzhou Road, Nanning, Guangxi, China

Tel:+86-13877625497

Name:Mr.Chintu

Fax:

Website:https://www.cokgc.com/

E-mail:COMKGC@163.COM

Tel:+86-13877625497

Name:Mr.Chintu

Fax:

Website:https://www.cokgc.com/

E-mail:COMKGC@163.COM

Current:Home > +Power plant IPP

+Power plant IPP

Load cell for weight bridge

2016-01-20 20:35:20

-- "Load cell for weight bridge of Raw Coal Feeder (F55 Pressure tight Weighing)

offers 10 VDC(+/-10%),500mA excited power, Sensitivity:0.5-3.5 mV/V

Model No: 9355K-100 kg

|

SHAFT;P/N:NJCG-QSZZ;TYP COC DRIVE |

SHAFT; |

|

DRIVE PULLEY |

Drive Pulley of Raw Coal Feeder (F55 Pressure tight Weighing) |

|

DRIVEN PULLEY |

Driven Pulley of Raw Coal Feeder (F55 Pressure tight Weighing) |

.jpg)

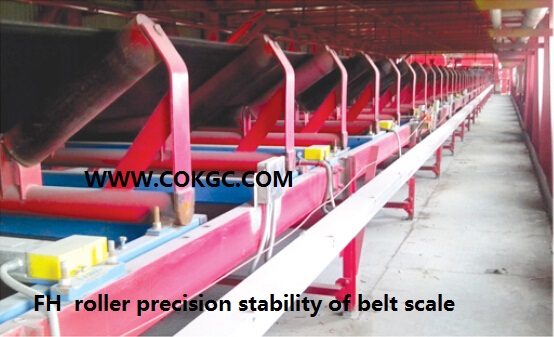

| FH - roller precision stability belt scale USES four groups of double roller floating scale scale formed, weekly scale USES the free floating balance structure, break through the traditional design concept, the infinite structure, double weighing sensor direct force, high precision measurement.I side with PLR - D digital converter, the scene to direct convert analog to digital quantity far to FH - 03 type weighing instrument, speed measuring device for PLR - 12 rs.FH - 8 series of belt scale dynamic accumulative error of 0.2-0.5%, for belt conveyor length within 200 meters of all kinds of weighing requiring higher precision. |

.jpg)

| Electronic belt weigher batching system Belt scale batching control system is mainly composed of electronic belt scale, electric control system and computer management system of three parts.The system adopts the general form of industrial computer man-machine interface, it has the data acquisition, control, alarm, graphics, and data display functions.According to the requirements set complete material proportioning control all kinds of data in the process of the production and management. |

| Electronic belt scale loading system ME, belt scale fast-loading system is superior to the traditional loading system solutions.Traditional loading system of investment and the high cost of maintenance, and belt scale through the belt scale, bin weighing system and loading system match the wagon balance, to provide users with low computer, high precision fast loading applications, and put an end to human interference factors, significantly improve the efficiency of the enterprise. Using high precision weighing system of silo and belt scale, real-time detection of weight loading bunker.Equipped with automatic control system for real-time input signal receiving and processing, including bin weight detection, bunker feed flow detection, carriages, tare weight of the train, car position and carriages on the gross weight, and automatically control and adjust the loading weight of each compartment.Friendly human-machine interface, easy to intuitive manage and monitor the whole process of loading system.The content of the man-machine interface can be customized according to user's requirement. |

| Three electronic belt scale In global innovation launched three bridge series three series of belt scale, belt scale, build series belt scale, make it more reliable belt scale have higher stability and accuracy. Three series of belt scale opens the electronic belt scale of three times, a three belt scale has three sets of the total quantity: a set of main accumulation and two groups of auxiliary accumulated amount.Real-time online than in two groups of auxiliary accumulation, super bad, found the complementary cumulative quantity compares discriminant of weighing sensor, to determine whether the weighing sensor is faulty, there will be a failure of the weighing sensor of a set of auxiliary accumulation segregated, auxiliary accumulation by another group of normal automatically replace the main accumulation. At this point, the belt scale weighing work don't interrupt, system continues to run.To ensure a weighing sensor in belt scale there is failure, the system can still be measured reliably.Greatly improve the reliability of the electronic belt scale operation and the accuracy of the measuring accuracy.Is not allowed to avoid because of weighing sensor failure, metering, cause serious economic losses. Belt scale is widely adapted to the electric power, coal, metallurgy, mine, port, chemical industry, building materials industries such as the measurement of material. |

.jpg)

| Three bridge material since the calibration of electronic belt scale Three bridge auto-calibration belt scale using proprietary standard material stack calibration technique, solved the belt scale for many years is not easy to real world problem of calibration, can be on the existing belt conveyor, at low cost to realize automatic online belt scale material calibration. Three bridge auto-calibration belt scale USES two groups belt weighing bridge, a set of weighing hopper, a scraper reclaimer and screw conveyor.With few material (0.2% ~ 0.5% of transporting material flow, depending on actual working condition), solve the problem of the belt scale physical calibration.To realize low cost material online automatic calibration, ensure the operatio |